Hydra‑Bubble: The Future of Wastewater Mixing

Large bubble technology that slashes operating costs,

eliminates in-tank maintenance, and keeps systems clean and efficient

Large bubble technology that slashes operating costs,

eliminates in-tank maintenance, and keeps systems clean and efficient

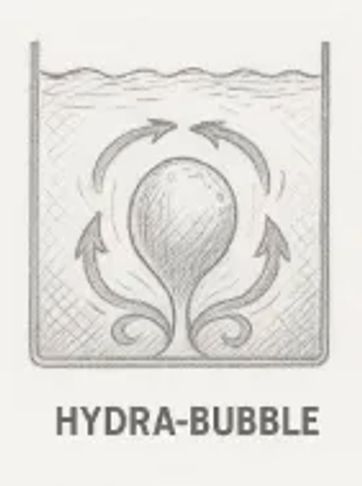

Uses the physics of buoyancy and hydraulic flow to generate powerful mixing. Each rising bubble displaces water with natural force, driving efficient circulation, no moving parts, just amplified energy from nature itself.

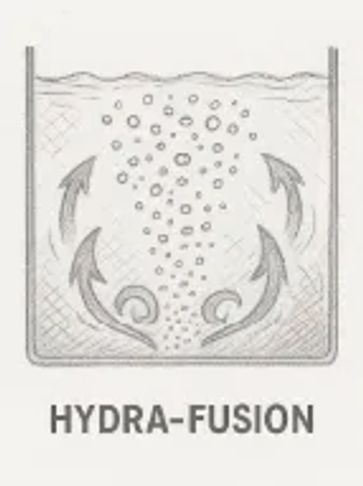

Combines large-bubble mixing with microbubble aeration to hold oxygen in suspension longer and boost biological contact, multiplying treatment efficiency .

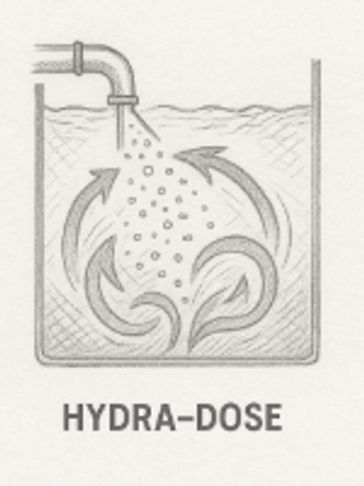

Uses large-bubble mixing to instantly disperse chemicals from top to bottom, ensuring fast, even distribution. The hydraulic rolling action enhances contact time and gentle agitation, making it ideal for flocculation and other chemistry-driven processes.

Hydra-Bubble™ is more than just a mixing system—it’s a nature-inspired, low-maintenance solution built for the people who design, operate, and own water and wastewater treatment systems.

At the heart of the technology is a flagship 1.5 cubic foot submerged air accumulator that passively fills and forcefully releases large, low-pressure air slugs using only the laws of physics. No electronics. No moving parts. No headaches.

As each bubble rises, it behaves like a piston, displacing water and generating powerful vertical and radial mixing currents. This motion eliminates dead zones, lifts and suspends solids, and ensures uniform circulation from bottom to top. The result is consistent performance, dramatically reduced energy use, and lower operating costs—all without any moving parts below the surface.

Hydra-Bubble combines elegant physics with real-world reliability to deliver a truly complete mixing solution.

Hydra-Fusion™ combines fine-bubble aeration with Hydra-Bubble’s powerful mixing to create a highly efficient treatment environment. The large bubbles generate strong circulation that hold microbubbles in suspension 2–3 times longer, greatly improving oxygen transfer and biological contact.

The system is highly adaptable: Hydra-Fusion can be applied by pairing Hydra-Bubble with an existing fine-bubble aeration tank, or Hydra-Bubble units themselves can be outfitted with fine-bubble diffusers. This allows them to be used in-situ—such as in lagoons, drop-in installations, or other situations where flexible deployment is required.

This synergy keeps dissolved oxygen distributed evenly, prevents solids from settling, and enhances biological performance throughout the tank or lagoon. Hydra-Fusion turns two proven technologies into one optimized, energy-saving process—delivering results that outperform either system alone.

Hydra-Dose™ uses large-bubble mixing to instantly disperse chemicals from the bottom of the tank to the top, ensuring rapid, uniform contact. The dosing agent is first introduced directly into the Hydra-Dose unit, where it is briefly held until the moment when air begins rushing out of the unit. At that point, the agent is pulled into an intense zone of turbulence where water and air violently churn together, vigorously agitating and blending the solution.

From there, the air pulse launches the mixed chemical outward, entraining it into the surrounding water column. The release creates both an upward plume and a swirling lateral motion, which together carry the agent evenly through the full tank volume. This dynamic mixing ensures the solution is distributed consistently and effectively throughout the system.

Because the chemical disperses so quickly and thoroughly, control systems detect water-quality changes faster and adjust more accurately—reducing overdosing, cutting chemical waste, and lowering operating costs. The hydraulic rolling action also supports gentle, uniform suspension for applications like flocculation, where both contact time and stability are critical. Hydra-Dose turns simple air pulses into a smarter, cleaner, and more cost-effective way to dose and distribute treatment chemicals.

Hydra-Bubble™ is more than just a mixing system—it's a complete solution designed for the people who design, operate, and own treatment systems. At the heart of the technology is a flagship 1.5 cubic foot submerged air accumulator that passively fills and forcefully releases air slugs, using only the laws of physics. No electronics. No moving parts. No headaches.

Engineers appreciate that Hydra-Bubble delivers mixing power without complexity. It provides, you are in control of the process:

- Consistent and physics-based mixing that works with your process model, not stuck with another companies models and delivery system. You make the changes when you need to make them.

- Fully detailed CAD models—to-scale and ready to drop into your layout

- A comprehensive Bill of Materials (BOM) with every submittal

- Integration support with SCADA, valves, and blower systems

We also have an on-staff biological engineer to assist with design questions, process matching, and biological compatibility. Our team is highly responsive and easy to work with. You’re never left alone to “figure it out”—we’re here to make you look good.

Have confident in your design, supported by pros, and glad you didn’t spec another over-complicated mixer.

Operators love that Hydra-Bubble is maintenance-free and brutally simple.

- No motors, gearboxes, or bearings to fail

- No surface equipment to grease or inspect

- Just air, a tank, and the physical properties of buoyancy

Hydra-Bubble offers repeatable, full-depth mixing with no mechanical hassle—and if something’s unclear, we’ll walk you through it. We’ll even help with retrofits, send install drawings, and we will guide you step-by-step.

Feel relieved. It works. You don’t have to touch it. Save money on the power bill. And if you need anything, we actually answer the phone.

Owners care about capital cost, energy use, and reliability. Hydra-Bubble delivers on all three:

- Uses no electronics or control systems—less cost, less downtime

- Works with existing air systems (or new ones—we help size them)

- Delivers up to 10x more mixing intensity per volume than coarse bubble systems

- Doubles as a non-oxygenating anoxic mixer, eliminating the need for costly mechanical systems in many zones

Even better, we support every installation with precise CAD deliverables, a clear scope, and hands-on collaboration. Whether it’s new construction or a retrofit, we’ll get you through it without change orders or surprises.

Know you made a smart, low-risk investment in a system that actually works—and with a company that’s got your back.

- Responsiveness: Fast answers, clear timelines, and no ghosting.

- Precision CAD: Fully modeled in SolidWorks with scale-accurate geometry.

- Detailed BOMs: You know what’s coming, how it fits, and how to install it.

- Biological Process Support: Our in-house biological engineer ensures we speak your process language.

- Total Collaboration: We’re not just selling hardware—we’re here to help solve your mixing and process challenges.

Our team delivers expert technical support for every system we provide, ensuring consistent performance, long-term reliability, and peace of mind.

Hydra-Bubble™ generates massive circulation with each air pulse, creating a rolling hydraulic action that sweeps the entire tank. Unlike mechanical mixers, there are no dead zones or corners where solids can settle. This ensures complete bottom-to-top mixing and keeps the whole volume of water active—whether in small process tanks or massive municipal basins. Operators gain confidence that their system is always fully engaged and free of buildup.

By using large, low-pressure bubbles instead of high-speed impellers, Hydra-Bubble™ achieves superior mixing at a fraction of the energy cost. The natural buoyancy of air does the work, meaning less horsepower, less maintenance, and lower operating expenses. For engineers and owners, this translates into proven performance with measurable OPEX savings—without sacrificing reliability or process control.

Hydra-Bubble™ units are designed to be drop-in, anchor-mounted, and easy to install or relocate as needs change. They can be deployed in retrofits, lagoons, or new builds without costly infrastructure changes. Maintenance is minimal—no moving parts underwater, no gearboxes to fail—so operators spend less time troubleshooting and more time running their plant with confidence. The result is a solution that adapts to real-world demands and provides lasting peace of mind.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.